stochastic Quantifying Soiling Loss (SQSL)

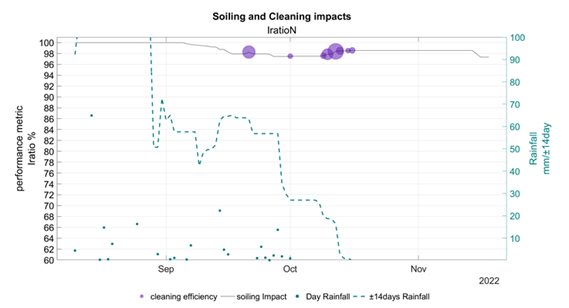

In the literature, among others, two methods can be found to measure soiling: the Fixed Rate Precipitation (FRP) model and the Stochastic Rate and Recovery (SRR) model. The FRP model applies a fixed soiling rate to all dry periods, generating a soiling profile. It requires a performance metric and rainfall pattern as inputs, but may fail to detect non-rainfall-related cleanings. On the other hand, the SRR model calculates the soiling rates between each pair of consecutive cleaning events. It generates potential soiling profiles using a Monte Carlo simulation, providing an alternative approach to soiling detection.

SerendiPV project introduces an innovative approach: the Stochastic Quantifying Soiling Loss (SQSL) method, developed by CEA-INES since 2022. The SQSL method offers a more sophisticated way to measure soiling. It does not require environmental data or information about artificial cleaning operations. Instead, it calculates the soiling impact directly from the electrical data measured in solar power plants. Unlike the SRR approach, SQSL does not look for change points or clean-only days. It considers a performance metrics profile, classifying days into cleaning days, stable periods, and soiling periods based on the performance metrics.

The SQSL method uses the Monte Carlo method to generate many random performance metrics profiles based on the probability distributions of different parameters such as frequency and duration distributions, soiling rate distributions, etc. This allows for the estimation of the most likely average soiling ratio and the uncertainty interval, providing a range of scenarios from the most pessimistic to the most optimistic according to the desired risk level.

Moreover, the SQSL method allows for the generation of future soiling profiles. This predictive capability can help identify the most cost-effective cleaning frequencies and dates in advance, contributing to more efficient maintenance planning and potentially significant cost savings.

Soiling Sensors: Soilratio & E-Dust

Soiling can cause non-homogeneous dust patterns that significantly affect the maximum power point, resulting in higher energy losses than those estimated by traditional soiling sensors. These sensors, which use optical methods or compare the short-circuit current of clean and dusted solar devices, may not accurately reflect the real effective power losses in PV modules due to their inability to account for the impact of uneven soiling distribution.

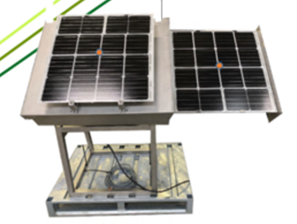

Automatic soiling sensors, while practical as they can operate without manual intervention, are currently unable to be integrated into real PV arrays. Instead, they are part of an independent static semiportable structure, which may not fully represent dust accumulation patterns, especially when compared to tracking structures. Moreover, manual dry cleaning is often more reliable than automatic wet cleaning of sensors when dust deposition is significant. Therefore, while these sensors provide valuable data, their limitations must be considered when assessing the impact of soiling on PV module performance.

The SerendiPV consortium has considered developing soiling sensors to address the effective power affection in PV modules and tackle the challenges mentioned above.

One of innovations introduced is the SoilRatio sensor, developed by CEA-INES. The concept consists in protecting one of the two PV sensors with a cover between each measurement, to keep it as clean as possible. In this way, this sensor does not require any cleaning, which guarantees better accuracy and lower operating costs. The latest update of SoilRatio integrates specific multi-zone panels, each zone being an independent sensor, thus allowing a more precise identification of the soiling type. The post treatment algorithm collects these multi-zones measurements and extrapolates them to the whole PV plant considering the electrical architecture, in particular the bypass diodes, to calculate the real electrical impact on the whole PV installation.

Another innovation presented in the SerendiPV project is the E-Dust prototype, developed by QPV. It is based on the use of two PV modules (clean and dusted) from the same batches, installed in the same structures and exposed to the same wind and tracking conditions as the rest of PV modules that make up the PV plant. The full I-V curve of both modules is simultaneously and periodically measured. As a comparative measure is carried out, no specific calibration is needed, as the system auto calibrates itself when both modules are cleaned.

More information about SerendiPV innovations on soiling can be found in the document: SerendiPV Innovations on Soiling Detection

Do you need more information on the serendipv soiling innovations?

Consult the webpage summarising the soiling innovations or consult the extended document presenting the SerendiPV innovations.